rockwell hardness test a|rockwell hardness test pdf : white label The Rockwell hardness test measures hardness in progressive numbers on different scales corresponding to the size of ball indentor used; scale symbols correspond to the loads of 60 . 4,301 likes, 86 comments - andreiagadelhapro on January 27, 2024: "”Eu sou capaz de enfrentar qualquer desafio que a vida me apresente e alcançar meus objetivos ." Andreia Gadelha ⭕️ on Instagram: "”Eu sou capaz de enfrentar qualquer desafio que a vida me apresente e alcançar meus objetivos com perseverança e determinação.”

{plog:ftitle_list}

WEBReach out to us at [email protected] or click the Help beacon in the bottom right corner of the screen if you're still having trouble! Julius is a powerful AI data analyst that helps you analyze and visualize your data. Chat with your data, create graphs, build forecasting models, and more.

The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test.

Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the .Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the .

Rockwell Hardness Testing Reference Guide. ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your .

The Rockwell hardness test measures hardness in progressive numbers on different scales corresponding to the size of ball indentor used; scale symbols correspond to the loads of 60 .The Rockwell hardness test is applied globally for the application of an experimental indentation hardness test. The Rockwell test is a quick process, very cost-effective, and non-destructive test (causing only minor indentation on the specimen material). The Rockwell hardness test is a simple process that is why it can be performed by anyone . In this video I go over the Rockwell Hardness test with an analog machine. This is a Wilson machine.I talk about the setup for Rockwell “A” , “B” and “C” tes.

The Rockwell hardness testing method fulfilled every requirement. After 100 years, it’s still the best metal strength test method. The Rockwell C scale is also the most precise way to report metal strength used in industrial machine .The Rockwell Hardness Test Method, as defined in ASTM E-18 is the most used hardness test. It is easy to perform, and more accurate than other types of hardness tests. In our lab, we used Rockwell method to measure the permanent depth of the indentation produced by a load on an indenter. Before the test, we studied the material prior to .These approximate relationships between hardness and tensile strength do not apply to nonferrous metals, with the possible exception of certain aluminum alloys. Related: Brinell Hardness Testing Equation. Table A Brinell Hardness to Rockwell Hardness Conversion Table

HR-150A Manual Metal Micro Hardness Tester Instrument Durometer Desktop Rockwell Hardness Test Machine. 1 offer from ,19900 $ 1,199 00. Hardness Tester Rockwell Type HR 150A 150 Max Load Testing Table Test Block. 1 offer from ,45077 $ 1,450 77. Next set of slides. Looking for specific info? Product information .We would like to show you a description here but the site won’t allow us.The U S Mint uses a Rockwell Hardness Test on all raw coin material (including copper- plated zinc blanks). (US Mint, E-mail 8/24/2015, Diamond, 2006, Page 16). The test procedure involves pressing a 1/16″ metal ball into the coin material with a known amount of pressure and measuring the depth of penetration. There are other Rockwell Scale .Set includes six files and a chart to convert to Vickers scale. It is an economical way to determine the hardness of steel on the Rockwell C-scale.Handles are marked with Rockwell hardness values. If a file can scratch your material, then your material is softer than the file. If a file cannot scratch your material, then your material is harder than the file.

How To Operate The Analog Rockwell Hardness Tester ; Cylindrical Correction Chart; Hardness Conversion Chart - Rockwell "B" Hardness Range; Hardness Conversion Chart - Rockwell "C" Hardness Range; Hardness vs Minimum Thickness Chart; Rockwell Scale-Indenter-Load Chart; Contact Us. About Us; Store Policies; BlogISO 6508-3, Metallic materials — Rockwell hardness test — Part 3: Calibration of reference blocks 3 Terms and definitions No terms and definitions are listed in this document. ISO and IEC maintain terminology databases for use in standardization at the following addresses:

rockwell hardness testing chart

Different series of aluminum alloys have different hardness values; for example, there are differences between the hardness of 7075 aluminum alloy and 6063 aluminum alloy. Furthermore, the hardness of aluminum alloys can also be measured with specific hardness testers, such as Vickers hardness testers, and the Rockwell hardness testing method. Rockwell Hardness Testing The Rockwell hardness test method is a destructive type test It consists of indenting in the test material with a diamond cone or hardened steel ball indenter. The indenter is forced into the test material under applied load and make a dent inside the specimen The movement of the indenter is measure by . 12. Working Principle 1. SELECTING THE HEAD AND TEST BLOCK Hardened steel and hard alloys like Cast Iron were tested in the Rockwell C scale, using a diamond cone as head and a 150 kg major load. Brass was tested in B scale, using a 1/16” ball as head and a 100 kg major load. Copper was tested in F scale, using a 1/16” ball as head and 60 kg major load. Aim: To determine the rockwell hardness number of the given sample.

supcase iphone se drop test

One of the challenges with the Blaser is I can't hardness test the bolt as its a collet. turbo54 Mr. 7mm. Full Member. Minuteman. Dec 10, 2010 4,995 31 44 Michigan. Aug 25, 2012 #4 Aug 25, 2012 #4 Re: Rockwell hardness levels - in real life? I'm still confused what you're actually asking about. Yes, conventional wisdom says locking lugs on the .Rockwell Hardness Testing File Sets . Set includes six files and a chart to convert to Vickers scale. It is an economical way to determine the hardness of steel on the Rockwell C-scale. Handles are marked with Rockwell hardness values. If a file can scratch your material, then your material is softer than the file.

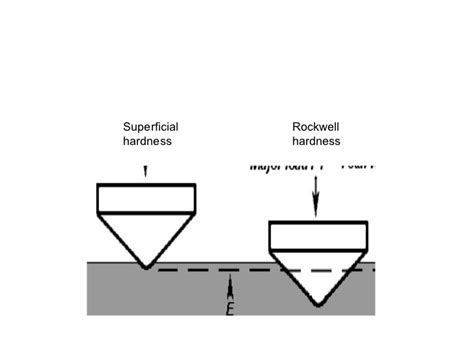

The Rockwell hardness test In the Rockwell test, a spherical indenter is used for softer materials (Rockwell B scale), and a conical indenter is used for hard materials (Rockwell C scale) is used. The test-piece, which needs no preparation .

supcase note 9 drop test

rockwell hardness tester diagram

Experiment 7: Rockwell Hardness Test - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. (1) The Rockwell hardness test is a common method to determine the hardness of metals and polymers using indentation. (2) An indenter applies a minor preload and then a major load, and the hardness number is based on the . The Rockwell hardness test remains the most efficient and widely used hardness test today and is recognized as one of the 20th century’s metallurgical innovations. Learn More Documents. Rockwell, Hugh M., and Stanley P. Rockwell. Patent Number 1,294,171 - Hardness Tester. 1,294,171. Bristol, CT, issued February 11, 1919.Please contact us here: 1- 888-400-4243 (USA & Canada) 1-631-321-0160 (International) WESTport Corporation 510 Montauk Highway West Islip, NY 11795

The Rockwell hardness test was invented in 1914 by Hugh and Stanley Rockwell. It measures the hardness of materials by applying two loads with an indenter and measuring the depth of penetration. There are different Rockwell scales that use different loads and indenters depending on the material being tested, such as scales for metals, plastics .

Rockwell hardness test blocks are also used for verifying or comparing the performance of Rockwell hardness machines and indenters. The test method standards specify requirements for the preparation, size, finish, uniformity, and standardization of reference test blocks. Historically, Rockwell test blocks are standardized (also referred to as .Numerous aspects of the Rockwell hardness test can influence the measurement result. These include the function and calibration of individual components of the hardness machine, variations in the indenter, the testing cycle that is used, the testing environment, the condition of the test material, and the operator. When considering all of these influences, it seems remarkable that .Multiple test force generation for Rockwell, Rockwell Superficial and Brinell hardness. Dolphin-nose indenter arm for easy reach of interior (min. ø40mm/ø22mm*) and exterior surfaces. Real time electronic test force control for accurate loading. This .

The standard superficial Rockwell 15Y hardness test has been adapted for use on concrete. Hardness measurements were made on the mortar regions between the coarse aggregate pieces. A correlation between this hardness and the concrete's compressive strength was developed. For 7.5- by 15-cm (3- by 6-in.) cylinders, it is Rockwell 15Y hardness .

Precision in hardness testing starts with the right support through hardness testing sample holders and anvils. Secure specimens, maintain stability during testing, and ensure the test surface is perpendicular to the indenter, guaranteeing trouble-free testing.

rockwell hardness test theory

12 de nov. de 2023 · Jujutsu Kaisen fans ridicule Gojo's most famous line. Screenshot of "Nah, I'd win" meme (Image via Sportskeeda/X) Jujutsu Kaisen chapter 221 saw the .

rockwell hardness test a|rockwell hardness test pdf